Desulfurization/denitrification

Flue gas desulfurizer

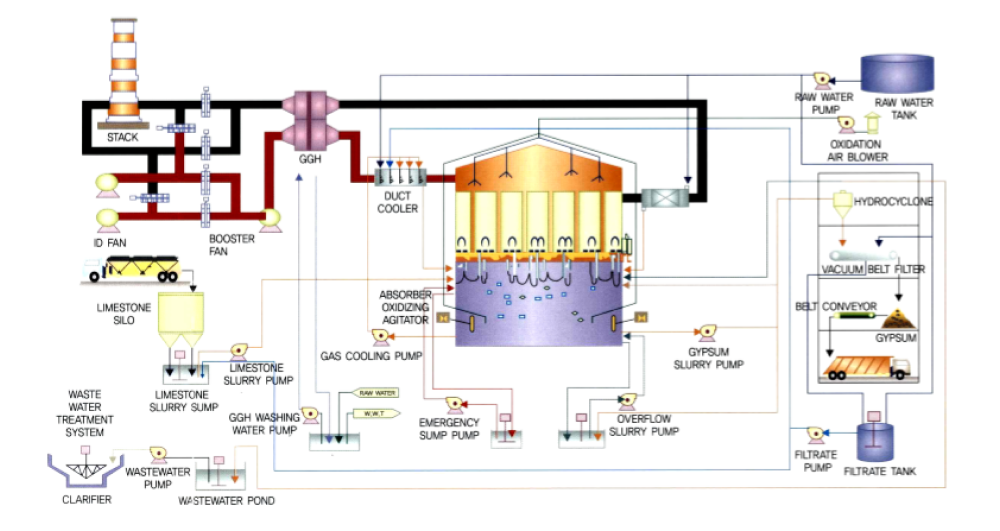

A flue gas desulfurizer (FGD) is a facility that removes sulfur oxides, which are the main causes of acid rain and respiratory and skin diseases. Sulfur oxides reduction technology is largely divided into wet and dry desulfurization, with wet desulfurization (Wet FGD) accounting for nearly 87% globally. Wet Lime-Gypsum FGD System is widely used for its outstanding desulfurization efficiency, reliability, and economic viability.

KEPCO E&C has developed Korea Electric Power Absorption Reactor (KEPAR), featuring its unique gas bed perforated plate desulfurization absorption tower design.

Schematic diagram of KEPAR

Features

- High desulfurization efficiency

- High economic viability based on its compact design

- High-purity gypsum quality

- Low COD concentration of desulfurized wastewater

Track records

- 1200 MW Yeongdong Units 1 and 2 and Seocheon Units 1 and 2

- 2350 MW Pyeongtaek Unit 1 desulfurizer

- 3100 MW Namjeju Units 3 and 4 desulfurizer

- 4500 MW Boryeong Units 1 and 2 desulfurizer

- 5Patent application in Korea, Japan, USA, Germany, and China

Flue Gas Denitrification System

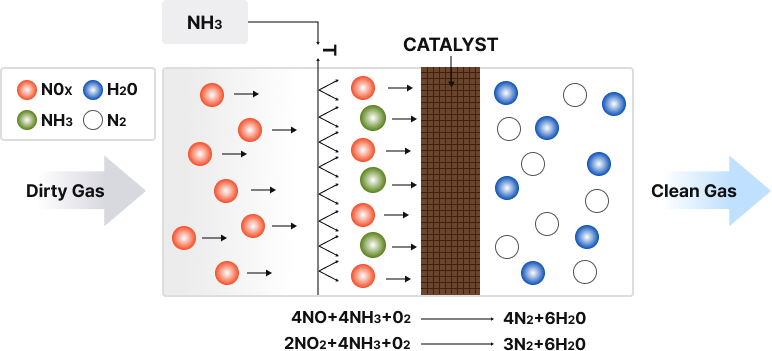

Flue gas denitrification system (DeNox System) removes nitrogen oxides, the main cause of acid rain and photochemical smog. Nitrogen oxides reduction technology can be divided into three parts: pre-combustion denitrification, combustion condition improvement, post-combustion denitrification. The reduction efficiency, in terms of the improvements in pre-combustion denitrification and combustion conditions, cannot exceed 60%, so most of the fossil fuel-based DeNox Systems in the power plants apply post-combustion denitrification technology with higher denitrification efficiency. The selective catalytic reduction (SCR), among others, is widely used around the world for its outstanding denitrification efficiency and high reliability.

Starting with the design of flue gas denitrification facilities for Seoul Thermal Power Plant, KEPCO E&C has successfully carried out design and construction supervision services for flue gas denitrification facilities for most domestic power plants, establishing itself as one of the top-tier denitrification system design firms in Korea.

Chemical equation

Chemical equation 4NO + 4NH₃+ O₂→ 4N₂+ 6H₂O / NO + NO₂+ 2NH₃→ 2N₂+ 3H₂O

Track records

- 1 Design & engineering services for the performance improvement of denitrification facilities for Taean Units 7 and 8

- 2 Feasibility study for the performance improvement of Yeosu denitrification facilities

- 3 Design & engineering services for the installation of new denitrification facilities for Ulsan Combined Cycle Power Plant Units #1-3