Other SMRs

i-SMR(Innovative SMR)

- 2020 ~

- 170MWe

- Integrated SMR (for offshore)

- Government-led preliminary feasibility project

SMART

- 1997 ~

- 110MWe

- Integrated SMR (for land use)

- Led by KAERI

Sodium fast reactor (SFR)

- 2012 ~

- 150 MWe or more

- 4Th-generation generation non-light water (for land use

- Led by KAERI

i-SMR

SMR denotes a nuclear reactor with an electrical output of up to 300 MW that is designed to enable nuclear reactor parts to be produced as modules in a factory and be easily assembled on site. As of 2022, around 80 types of SMRs are under development globally. KEPCO E&C participated in the government-led innovative SMR Phase 1 technology development (2021 - 2023), performing concept draft, top-level requirements development, and basic design with its plan to participate in Phase 2 technology development (2023 - 2028) for developing an innovative SMR standard design and capitalize on licensing contracts.

Technology development goals

Achieving the world’s highest-level safety

Core damage frequency: 1.0x10-9/M-Y

Securing economic feasibility at the level of large nuclear reactor plants

Construction cost: USD 3,500/kWe

Power generation cost: USD 65 /MWh

Securing flexibility (Flexible operation)

Output range: 100% - 20% - 100%

Linear output change rate: 5%/min

Application of KEPCO E&C’s technology, “Built-in control rod drive mechanism and boric acid-free operation design”

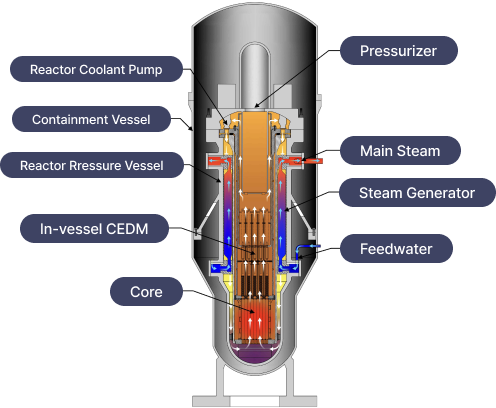

i-SMR has improved safety by installing the steam generator, pressurizer, reactor core, and control rod drive mechanism, which are the main devices of a nuclear reactor system, in a pressure vessel, preventing a coolant leakage caused by a large-diameter pipe rupture. The nuclear reactor is sealed inside a steel containment vessel with a thickness of at least 30 ㎝, and the steel containment vessel is designed to withstand much higher pressure than currently operating nuclear reactor plants. Moreover, it increases the durability of devices, reduces radioactive waste generation, and simplifies the system by not using boric acid in the coolant.

Its design is characterized by improving safety with a completely passive safety system that does not require safety-grade power and an operator, thus eliminating the possibility of serious accidents such as explosions and radiation leaks. It has secured economic efficiency at the level of a large nuclear reactor plant through the integrated reactor, precision manufacturing, and system simplification and expands flexibility in its output scale and utilization through flexible operations linked to renewable energy, diversification of its output scale through a modular design, and multipurpose use coupled with power generation.

In particular, the built-in control rod drive mechanism (IV-CEDM), which fundamentally prevents control rod separation accidents, and boric acid-free operation design are unrivaled proprietary technologies of KEPCO E&C.

Key Features of i-SMR

Conceptual design (2 years)

2023 - 2024

Basic design (3 years)

2025 - 2027

Standard design & licensing (5 years)

2028 - 2032

Small & medium-sized nuclear power plant, SMART (System-integrated modular advanced reactor)

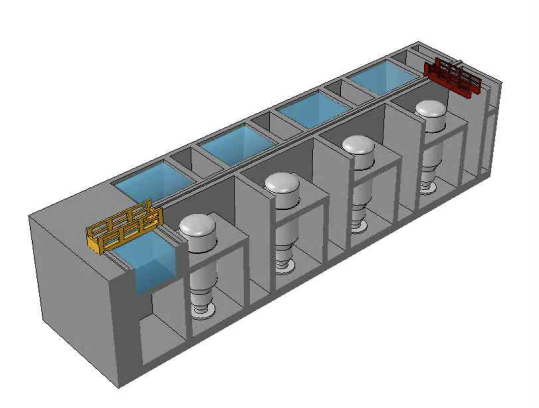

The SMART nuclear power plant is an integrated nuclear reactor in which the nuclear reactor, steam generator, pressurizer, and coolant pump are integrated into one vessel. It features a capacity of 1/14th of a commercial nuclear reactor (100 MW) and can supply water and heating through electricity and seawater desalination to a city with a population of 100,000. In particular, the demand for SMART nuclear power plants is expected to increase in developing countries that do not have large-scale integrated power grids. There are approximately 120,000 power plants with a capacity of up to 300 MW in operation globally, of which 18,400 are 30 years or older and use fossil fuels. The SMART nuclear power plant is expected to replace them within the small power generation market. KEPCO E&C performed a comprehensive design and reactor system design to develop the standard design of SMART nuclear power plants and obtain a standard design approval for its SMART nuclear power plant from the Nuclear Safety and Security Commission in July 2012. Moreover, KEPCO E&C performed the “Comprehensive design of pre-construction SMART nuclear power plants” pursuant to the “Korea-Saudi Smart Nuclear Power Plant Pre-Project Engineering (PPE) Agreement” that was signed between South Korea and Saudi Arabia. Accordingly, we completed the development of the significantly improved passive SMART nuclear power plant (SMART100) in December 2018.

Sodium-cooled fast reactor (SFR)

4th-generation nuclear reactor with incineration function for toxic substances from spent nuclear fuel

SFR is the latest nuclear reactor type currently in research and development to satisfy the technical goals of the 4th generation nuclear reactor with characteristics like sustainability, economic feasibility, safety, and nuclear proliferation resistance. KEPCO E&C has been developing an SFR prototype reactor featuring the function of incinerating toxic substances from pressurized water reactor spent nuclear fuel since 2012. Through its design, toxic nuclides (such as transuranium) are recovered from pyroprocessing for spent nuclear fuel of the pressurized water reactor and effectively burned in an SFR furnace to reduce the amount of spent nuclear fuel disposal ultimately. Also, the pool-type SFR prototype reactor has an electric capacity of 150 MWe. The primary heat transport system of the SFR prototype reactor forms the primary coolant boundary, while the intermediate heat transfer system prevents any impact on the reactor safety even in the event of a sodium-water reaction occurring in the steam generator. Given that the main equipment and pipes that make up the primary heat transport system are installed inside the reactor vessel, there is no possibility of coolant loss even in the case of a virtual pipe rupture, and it has sufficient thermal inertia to alleviate rapid thermal transients that are expected, regardless of an accident. The nuclear reactor plant/facility is designed to support safety systems, equipment, and structures, including the nuclear reactor and primary heat transport system, and a seismic isolation system is installed at the bottom of the facility building to reduce any excessive shocks due to ground vibration. The reactor plant/facility is built to serve as a final barrier to block external leakage of radioactive materials in the event of a design-based accident and designed to maintain structural integrity even in the event of accidents exceeding design standards, such as severe accidents and aircraft collisions.