[Operation] Operation & Maintenance [Back-end management] Radioactive Waste disposal

[Operation] Safety evaluation / lifespan management

KEPCO E&C plays a pivotal role in safe nuclear power plant operations and stable power supply by providing technical services for periodic safety reviews - evaluations on the soundness of nuclear facilities - on operational power plants and safety evaluations for continued operations. With our technology for the evaluation, management, and analysis of aging deterioration such as fatigue, corrosion, and embrittlement that can affect facility soundness, we are conducting periodic safety reviews on all domestic nuclear power plants in operation every 10 years and safety evaluations on continued operations of some domestic operational nuclear power plants about to reach their design life(Kori Units 2,3,4, Hanbit Units 1,2, Hanul Units 1,2, and Wolseong Units 2,3,4). In addition, we have secured technology for probabilistic safety assessment(PSA) through continuous technology development and built technology for risk information utilization - a field of application for PSA. Every effort is also being made to improve safety of industrial facilities by evaluating the safety level of large industrial facilities such as nuclear power plants, petrochemical facilities and by identifying the areas in need of safety improvement.

Description

Periodic safety review (PSR)

PSR is a comprehensive safety evaluation conducted to secure a higher safety level, taking into account the effect of aging deterioration of the structures, systems, and equipment that make up reactor facilities, the utilization of domestic and international operational experience and research results, and the development of science and technology. This evaluation will enable us to secure the safety of nuclear facilities during the operational period of nuclear power plants

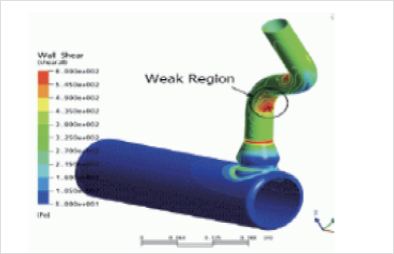

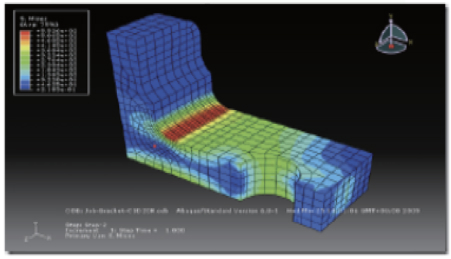

Evaluation and management of the equipment soundness

- Evaluation and management of the equipment soundness is a technology aimed at evaluating and systematically managing the soundness related to various aging deteriorations of nuclear equipment that can occur during operations.

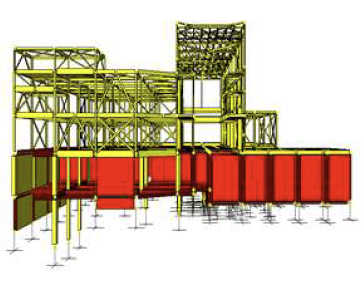

- Real Model

- A case for CFD/FEA analysis

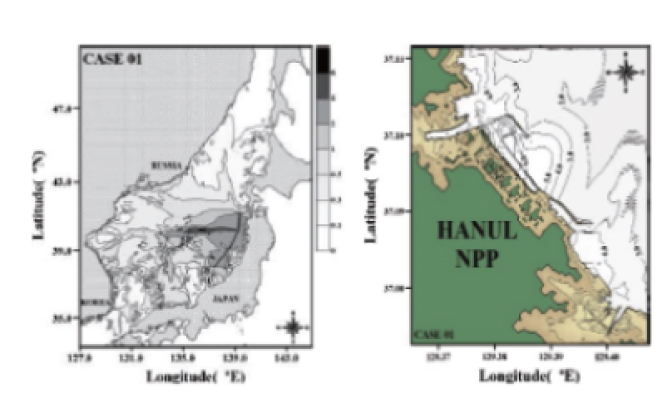

Stress tests for nuclear power plants

- Stress tests for nuclear power plants are aimed at evaluating the safety of the power plants and their response capabilities for beyond-design-basis extreme natural disasters such as earthquakes, and tsunami. This technology helps come up with and implement measures for improvement, enhancing the safety of nuclear power plants.

- The highest sea level caused by beyond-design-basis earthquakes and tsunami

Pipe wall-thinning management

- Pipe wall-thinning management is a technology that identifies the gradual thinning of pipes - caused by physical and electrochemical effects at work between carbon steel pipes and fluids of high temperature, high pressure, and high speed - and manages their soundness.

DB building stage

Building DB in each pipeline section

Analysis stage

Water chemistry/thermal hydraulics & thinning analysis

Area selection stage

Determination of areas based on analysis results

Inspection stage

UT inspection for selected areas

Evaluation stage

UT inspection data analysis & evaluation

Maintenance/replacement stage

Maintenance and replacement based on evaluation results

PSA(Probabilistic Safety Assessment)

- PSA improves the safety of industrial facilities by identifying all risk factors in large-scale industrial facilities, including nuclear reactor facilities and analyzes the accident development process to evaluate the probability and importance of an accident, identifying the main contributory factors that affect relevant risks through the process to derive countermeasures.

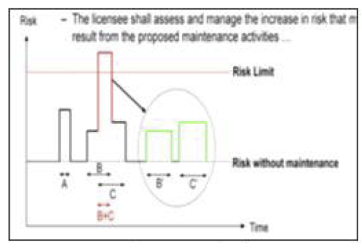

Risk information utilization

- Risk information utilization technology effectively improves the safety, operability, and economic viability of industrial facilities by comprehensively evaluating the extension of periodic inspection cycles and permitted outage time, and the revision of operational technical guidelines based on risk information.

- Risk management

- Risk monitoring system

Seismic performance evaluation

- Seismic performance evaluation technology evaluates the seismic safety of structures, systems, and equipment in large-scale industrial facilities such as nuclear power plants, petrochemical plants against beyond-design-basis earthquakes. This technology can enhance the safety of these facilities by identifying the vulnerabilities of industrial facilities to earthquakes and reinforcing and improving the seismic performance.

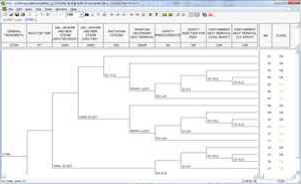

SAREX

- SAREX is a computer program for conducting PSA and reliability/utilization analysis for nuclear power plants and large-scale petrochemical industrial facilities, transportation facilities, complexes, etc. The users of SAREX can evaluate the safety and reliability of all facilities and individual systems

Event Tree Analyzer

Fault Tree Analyzer

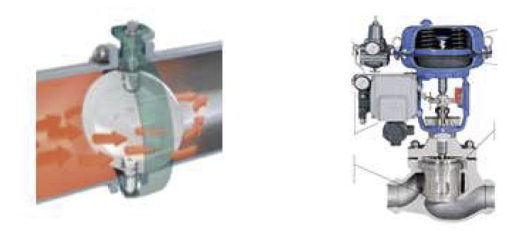

Valve performance evaluation technology

- The valve performance evaluation is about checking the operability of active motor-operated valves (MOV) and air-operated valves (AOV) related to the safety of nuclear power plants in operation and under construction. This technology contributes to enhancing the safety of nuclear power plants by evaluating the performance of valves which, in the event of accidents of nuclear power plants, play a pivotal role in mitigating the results of the accidents.

- Analysis of required force and actuator output