CFBC

CFBC

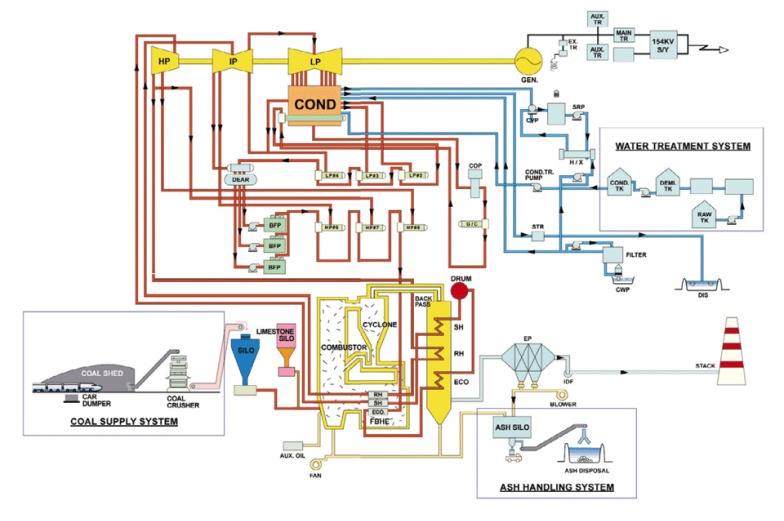

Circulating Fluidized Bed Combustion(CFBC) Boiler is an environment-friendly power facility to reduce the discharge of pollutants such as nitrogen oxide and sulfur oxide by injecting air and lime at the same time for burning. Significant amount of coal produced around the world is low grade coal, and because CFBC Boiler can completely burn low grade coal, it is highly economical.200MW class Donghae Thermal Power Plant Units 1 & 2 are the first power plants in Korea to apply Circulating Fluidized Bed Combustion (CFBC) Boiler method to promote consumption of domestic anthracites. KEPCO E&C performed A/E of Donghae Power Plant Units 1 & 2. Based on the knowhow accumulated from the A/E of Donghae Thermal Power Plant Units 1 & 2, we have successfully performed expansion project of Ulsan Petrochemical Industrial Complex Combined Heat & Power Plant and Geumho Combined Heat & Power Circulating Fluidized Bed Combustion (CFBC) Boiler.

Furthermore, we have performed overseas businesses including Circulating Fluidized Bed Combustion (CFBC) coal-fired thermal power plant construction feasibility survey in places such as Bayanteeg of Mongolia, Panay and Cebu of the Philippines, and Banko Barat of Indonesia.

KEPCO E&C also successfully completed A/E of Yeosu Thermal Power Plant Unit 2, which was applied 340MW class Circulating Fluidized Bed Combustion (CFBC) Boiler.

From 2009, we have been performing A/E for the world’s biggest class Samcheok Thermal Power Plant Units 1 & 2, which is applied Circulating Fluidized Bed Combustion (CFBC) method. Samcheok Thermal Power Plant Units 1 & 2 is the world’s biggest class Circulating Fluidized Bed Combustion (CFBC) variable pressure operated power plant composed of combination of 2 500MW class Circulating Fluidized Bed Combustion (CFBC) Boilers, and 1,000MW class Ultra Super-Critical Pressure Steam Turbine.

Characteristics of CFBC

The scope of fuel used is wide, and has high compatibility. Also, all the low grade coal can be burned without auxiliary fuel.

Without adding new facility, sulfur oxide (SOx) and nitrogen oxide (NOx) can be reduced to below the international standards.

Lime is burned at a low temperature below the melting point to solve Slagging and Fouling of coal.

Implementation references

- 1 Design and technical services for the construction of Donghae thermal power plant

- 2 Construction of Kumho TDF combustion combined heat and power plant

- 3 Comprehensive design and technical services for the construction of Samcheok green power units 1 and 2